Our Products

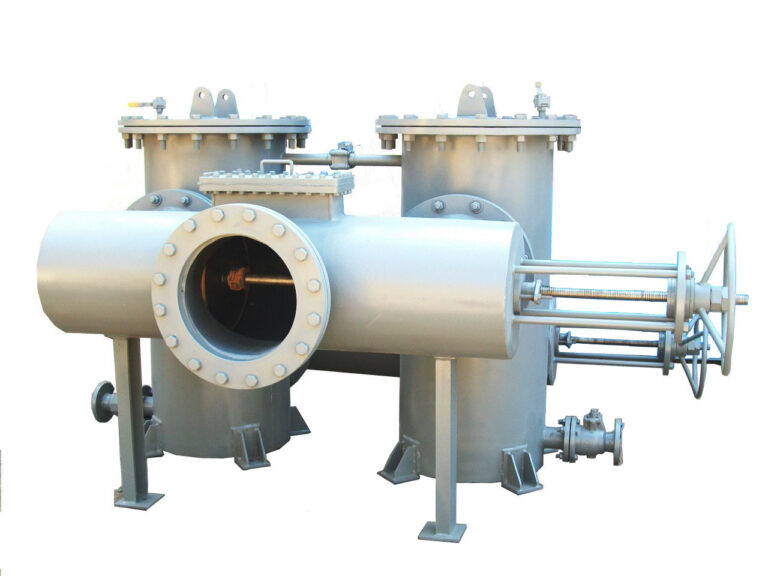

Automatic Self-Cleaning Backwash Strainers / Filters

MAHAPRABHA ENGINEERS AUTO SELF CLEANING FILTER consists of cylindrical body with suitable element housed in it. A rotating hollow arm is mounted inside the element for cleaning purpose. Whenever pressure drop exceed desired limit, arm is rotated by electric motor mounted on the top flange. Element will get cleaned without interruption of flow of fluid.

Filter consists of cylindrical housing with element housed inside. Liquid enters inside the element and flows out. Solids are retained inside. A hollow arm is provided on the center shaft for backwashing purposes. Backwash arm facing and close to the element inside surface, covering segment of element throughout its height (length) is rotated during backwash operation.

Geared motor is provided to rotate backwash arm so that complete surface of the element gets cleaned segment wise. DP Switch & Control Panel and Actuated Drain Valve are also provided for Auto Backwash operation at a preset value of Pressure Drop. Whenever Pressure Drop reaches preset value Backwashing cycle is initiated.

Duplex Basket Filters

It consists of cylindrical body with suitable element housed inside. Two such strainers / filters are connected together with common header having built in disc type valve inside for flow diversion, from one filter to another. By rotation of hand wheel provided at one end of header, valve disc moves to & fro for isolation of one of the strainers / filters, keeping other in operation. Built in valve could be disc type with combination of two headers one for inlet and other for outlet. There could be combination of common header with built in valve and butterfly valves.

At one time only one strainers / filters will remain in operation and another will remain as standby. Whenever pressure drop exceeds predetermined value, flow is to be diverted from clogged strainers / filters to other standby unit by rotation of hand wheel or valve handle.A DP switch is generally provided with electrical contacts for indication or alarm to initiate changeover operation from clogged unit to standby clean strainers / filters. Larger size units are provided with backwashing arrangement to clean choked element in place where it is difficult to remove element from body by opening top cover during every cycle.

For the larger size strainers / filters i.e. 16″ and above, though it is not necessary, electrical actuators can be provided for auto changeover operation when manual changeover operation is time consuming or not convenient.

For smaller size strainers / filters up to 4” NB size 6-port ball valve with single lever operation for changeover from one unit to another unit is preferred.

Simplex Basket Filters

Basket strainers are single bodied filters usually employed where process is not continuous or can be interrupted for maintenance. General applications include protection of pumps, valves, traps, spray nozzles, etc. amongst others.

Bag Filters

Bag filters are used for batch processes as well as continuous processes for removal of extremely fine particles. Bag filters can be used as in-line pre-filters to cartridge filters, thereby adding significant span to the life of cartridges.

Y Strainers

Usually installed in pipeline for coarse filtration and have less filtration area compared to basket filters

T Strainers

For installation at location in pipe work system that cannot be split to remove the screen. Suitable for installation in vertical pipeline also

Cartridge filters

Cartridge filters offer micronic level filtration for removal of very fine particles from fluids. They are also referred to as “Polishing” filters due to the finer degree of filtration associated with them. Useful for applications requiring clarification, i.e. removal of fine suspended solids or turbidity to achieve clarity of fluid

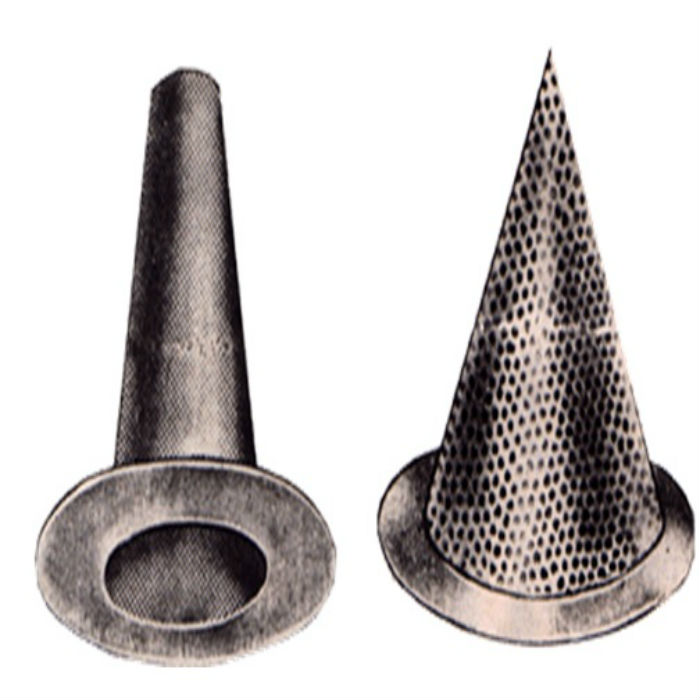

Conical Strainers

Designed for installation between flanges in pipeline. These are used during flushing operations / commissioning of plant and normally removed from pipeline once operation is complete.